Feed Mill & Agro Industries Automation PLC SCADA in Bangladesh

Bangladesh’s feed and agro industries are on the cusp of a revolution. Industrial automation, powered by programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems, is transforming the way crops are processed, livestock feed is produced, and resources are managed. This surge in automation is driven by a relentless pursuit of increased efficiency, improved product quality control, reduced production costs, and enhanced safety within these vital sectors.

Feed & Agro Processing in Bangladesh

Bangladesh boasts a thriving agricultural sector, contributing significantly to the nation’s GDP. The rise in demand for food security and high-quality agricultural products necessitates a modernized approach to processing and production. Feed mill automation is at the forefront of this change. By automating tasks like ingredient handling, mixing, and milling, feed mills can ensure consistent quality, reduce waste, and optimize production timelines.

A Wave of Automation Across Agro-Processing

The wave of automation extends far beyond feed mills. Rice processing, a cornerstone of Bangladesh’s agricultural landscape, is witnessing significant advancements. PLC control systems can automate tasks like paddy cleaning, hulling, and polishing, leading to higher yields and improved grain quality. Similarly, jute processing, another crucial sector, is benefiting from automation. Automated systems can manage tasks like softening, spinning, and weaving, leading to increased production capacity and enhanced product consistency.

Fertilizer production, another critical element in Bangladesh’s agricultural success story, is also embracing automation. PLC-based control systems can precisely regulate ingredient mixing, granulation, and packaging, ensuring the production of high-quality fertilizers essential for optimal crop growth.

PLCs and SCADA Orchestrating Industrial Harmony

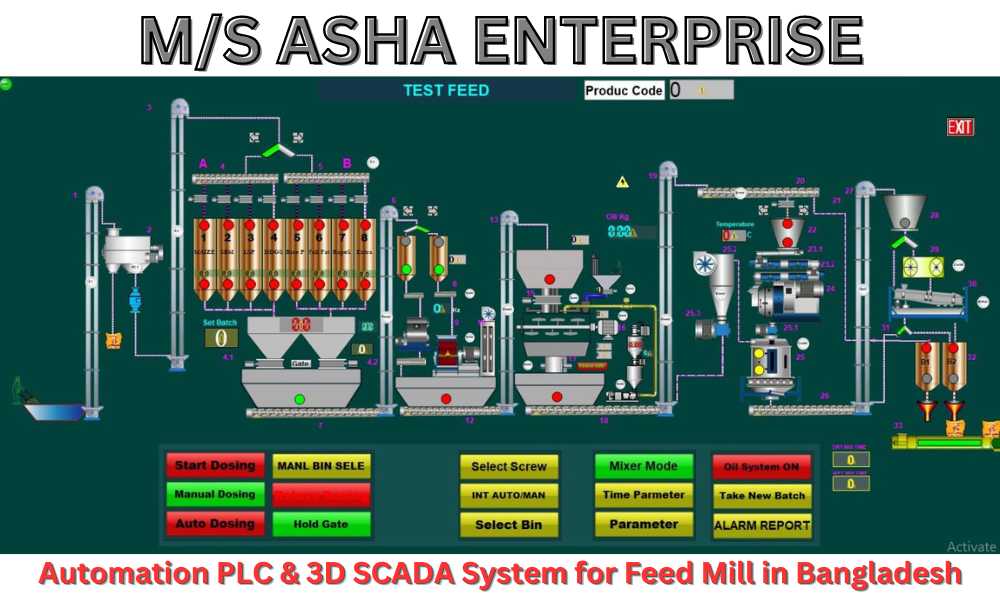

At the heart of this automation revolution lie two key technologies: PLCs and SCADA. PLCs, the workhorses of industrial automation, are essentially specialized computers that control physical processes. They receive input from sensors, make real-time decisions based on programmed logic, and send output signals to operate machinery. SCADA systems, on the other hand, act as the conductor, overseeing and monitoring the entire operation. SCADA can gather data from PLCs, HMI (Human-Machine Interface) panels, and other devices, providing a centralized platform for visualizing processes, analyzing trends, and issuing control commands.

Benefits of Automation in Feed & Agro Industries

The adoption of PLC and SCADA systems in Bangladesh’s feed and agro industries brings a multitude of benefits:

- Increased Efficiency: Automation streamlines processes, eliminates human error, and optimizes production schedules, leading to significant increases in overall efficiency.

- Improved Product Quality Control: Automated systems ensure consistent quality by precisely controlling parameters like ingredient ratios, processing times, and environmental conditions.

- Reduced Production Costs: Automation minimizes waste, lowers labor costs, and optimizes energy consumption, leading to significant cost reductions for feed and agro producers.

- Enhanced Safety in Feed & Agro Plants: Automating hazardous tasks minimizes the risk of accidents and injuries for plant personnel.

- Remote Monitoring and Control: SCADA systems enable real-time monitoring and control of operations from remote locations, facilitating proactive maintenance and swift response to potential issues.

A Look at Bangladesh’s Automation Landscape

As the demand for automation rises, so does the need for skilled professionals. PLC programming courses and industrial automation training programs are equipping a new generation of engineers and technicians with the expertise to design, implement, and maintain these sophisticated systems. Several prominent industrial automation companies in Bangladesh offer a range of services, from system design and development to PLC maintenance and troubleshooting. These companies, alongside PLC & SCADA suppliers, play a crucial role in enabling the smooth integration of automation solutions within feed and agro processing facilities.

Exploring the Broader Automation Spectrum

The impact of automation extends far beyond the feed and agro industries. Manufacturing Automation is transforming various sectors, including food & beverage, textile, pharmaceutical, and power plant automation. Industrial robots are automating tasks like welding, painting, and assembly, further enhancing efficiency and productivity. Process automation solutions are optimizing operations in chemical processing, oil & gas, and water treatment plants.

A Future Steeped in Automation

The future of Bangladesh’s industrial landscape is undoubtedly intertwined with automation. As technology continues to evolve, we can expect even more sophisticated PLC programming techniques, advanced SCADA systems, and the integration of artificial intelligence (AI) and machine learning (ML) into industrial processes. This confluence of technologies will further propel Bangladesh.

FAQ

What are the benefits of automating feed mills and agro-processing plants?

Automation with PLCs and SCADA offers a multitude of advantages, including increased efficiency, improved product quality control, reduced production costs, enhanced safety for workers, and remote monitoring capabilities.

What kind of training is available for PLC programming?

Several institutions offer PLC programming courses, equipping engineers and technicians with the skills to design, implement, and maintain these automated systems crucial for the feed & agro industries.

Where can I find PLC & SCADA suppliers in Bangladesh?

The rise of automation has led to a growing number of industrial automation companies in Bangladesh. These companies not only supply PLCs and SCADA systems but also offer services like system design, development, maintenance, and troubleshooting.