PLC Automation conveyor belt in Bangladesh

In the present manufacturing industry, automation is the way to progress. Mechanized frameworks take into consideration quicker and more proficient creation, reducing work costs and increasing in general efficiency. One such framework is the Programmable Rationale Regulator (PLC) automation conveyor belt in Bangladesh. PLC automation conveyor belts can be tracked down in various industries, including food and refreshment, drugs, and car. In Bangladesh, PLC automation conveyor belts are becoming increasingly famous because of their various benefits.

What is a PLC Automation Conveyor Belt?

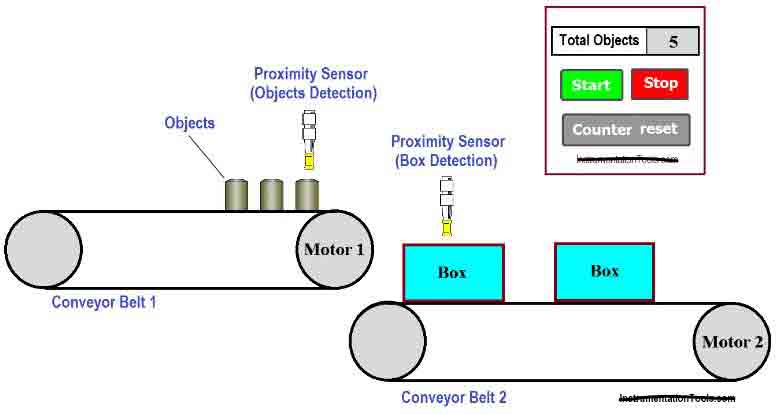

PLC automation conveyor belts are a sort of computerized conveyor belts framework that use Programmable Rationale Regulators (PLCs) to control the development of materials along the conveyor belt. PLCs are computerized PCs that are modified to control the activity of machinery and gear.

Would you like to increase the productivity of your manufacturing cycle and diminish work costs? Look no farther than PLC automation conveyor belts. In this article, we will investigate the benefits of using PLC automation conveyor belts in Bangladesh.

Benefits of Using PLC Automation Conveyor Belts in Bangladesh

- Increased Effectiveness: PLC automation conveyor belts are intended to increase the productivity of the manufacturing system. They can move materials at a quicker rate than customary conveyor belts, reducing the time it takes to deliver products.

- Diminished Work Expenses: Via automating the manufacturing system, work expenses can be decreased. With PLC automation conveyor belts, less specialists are expected to work the gear. This diminishes work costs as well as assists with improving generally speaking security in the working environment.

- Worked on Quality Control: PLC automation conveyor belts can be modified to perform quality control checks during the manufacturing system. This guarantees that any deficient items are recognized and taken out from the creation line, reducing waste and improving generally speaking item quality.

- Adaptability: PLC automation conveyor belts are profoundly adaptable and can be modified to play out different errands. They can be tweaked to meet the particular requirements of a business, allowing for more prominent proficiency and efficiency.

Industries that use PLC Automation Conveyor Belts in Bangladesh

- Food and Refreshment: In the food and drink industry, PLC automation conveyor belts are used to move ingredients, packaging materials, and finished items along the creation line. This assists with reducing the time it takes to deliver merchandise and work on generally speaking effectiveness.

- Drug: PLC automation conveyor belts are used in the drug industry to move materials through the creation cycle. They can perform quality control checks and guarantee that any flawed items are taken out from the creation line.

- Car: In the auto industry, PLC automation conveyor belts are used to move parts along the creation line. This assists with reducing work costs and work on generally proficiency.

Overall PLC Automation Conveyor

PLC automation conveyor belts are a fundamental part of current manufacturing processes. In Bangladesh, they are becoming increasingly well known because of their various benefits, including increased effectiveness, diminished work costs, worked on quality control, and adaptability. By implementing PLC automation conveyor belts in your business, you can further develop your creation cycle, lessen work costs, and eventually increase your profitability.