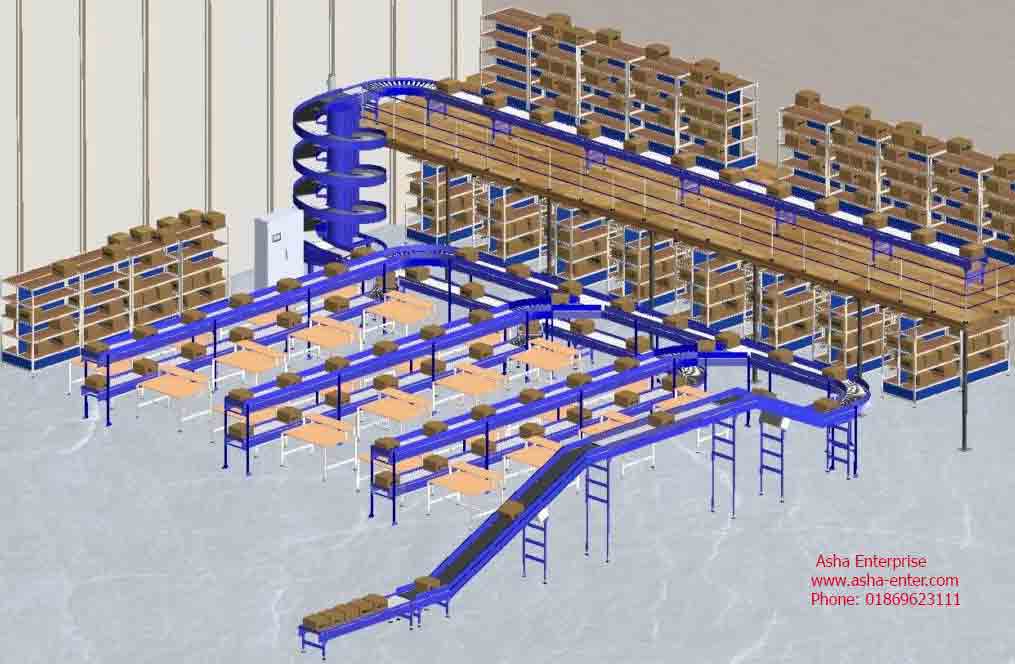

Warehouse Conveyor Belt In Bangladesh

In the speedy universe of present day coordinated operations, the proficient and opportune development of merchandise is vital to maintaining the progression of business. This is especially valid for warehouses and dissemination focuses, where the smooth and effective handling of inventory is central. One innovation that has demonstrated invaluable in such manner is the belt conveyor system in Bangladesh.

Automation conveyor belt in Bangladesh

Belt conveyor system are robotized, continuous transportation systems that are utilized to move materials and items starting with one area then onto the next within a stockroom or circulation focus. They are great for the handling of huge volumes of products over significant distances, and proposition various benefits over different forms of material handling hardware.

we will investigate the benefits of belt conveyor systems for warehouses in Bangladesh, and show the way that they can work on the efficiency, productivity, and productivity of your tasks.

Improved Efficiency

The first and most clear benefit of belt conveyor systems is that they work on the efficiency of your stockroom tasks. Via automating the development of merchandise, you can eliminate the requirement for physical work, which can be slow, inefficient, and inclined to mistake. With a conveyor system set up, you can move huge volumes of products rapidly and effectively, and with minimal human intervention.

This paces up the handling of products, yet in addition lessens the gamble of harm or misfortune. Conveyor systems are intended to be solid and sturdy, and can work all day, every day with minimal maintenance or personal time. This implies that your activities can run as expected and effectively, with minimal interruptions or postponements.

Increased Productivity

As well as improving efficiency, belt conveyor systems can likewise increase the productivity of your stockroom tasks. Via automating the development of merchandise, you can let loose your staff to zero in on additional significant undertakings, like quality control, inventory the board, and client care.

With a conveyor system set up, you can likewise deal with bigger volumes of products with less staff, which can assist you with saving on work expenses and increase your benefit. This is especially significant in a high speed climate like a distribution center, where there’s no time to waste and consistently counts.

Greater Flexibility

Belt conveyor systems are additionally exceptionally adaptable, and can be redone to meet the particular necessities of your stockroom or dispersion focus. They can be intended to deal with a great many products, including weighty, cumbersome, or sporadically molded things, and can be designed to suit your space and format.

Conveyor systems can likewise be integrated with different innovations, like mechanized stockpiling and recovery systems, to make a consistent and integrated material handling arrangement. This can assist with furthering work on the efficiency, productivity, and benefit of your tasks.

Reduced Environmental Impact

Belt conveyor systems can assist with reducing the environmental impact of your distribution center activities. By eliminating the requirement for manual handling and reducing the dependence on non-renewable energy source fueled hardware, conveyor systems can assist with reducing your carbon footprint and minimize your impact on the climate.

Belt conveyor systems are exceptionally energy-proficient, and can be intended to minimize energy utilization and decrease your operating expenses. This makes them a sustainable and practical answer for warehouses and dispersion focuses in Bangladesh and then some.